Design Center

w/Layouts and Patterns:

Unity has always been one step ahead of the competition. After being in the business for over twenty-five (25) years, we are committed to forward thinking and anticipating the needs of our clients. First, it was with the introduction of our self-interlocking products back in the early 90’s. More recently, we have created a new design feature to combat the problems that many architects, engineers and designers are facing. After months of planning and years of testing, we are proud to introduce the “Running Bond” Method of installation coupled with our “Button-Lock™ Technology for the spring of 2015.

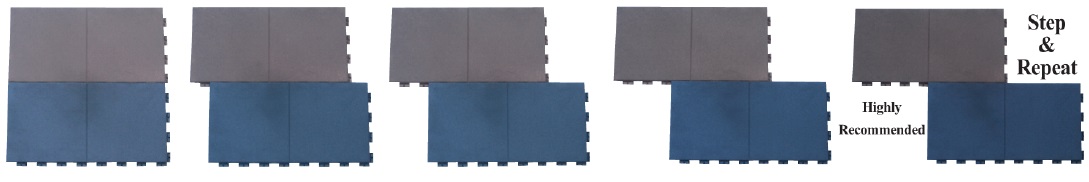

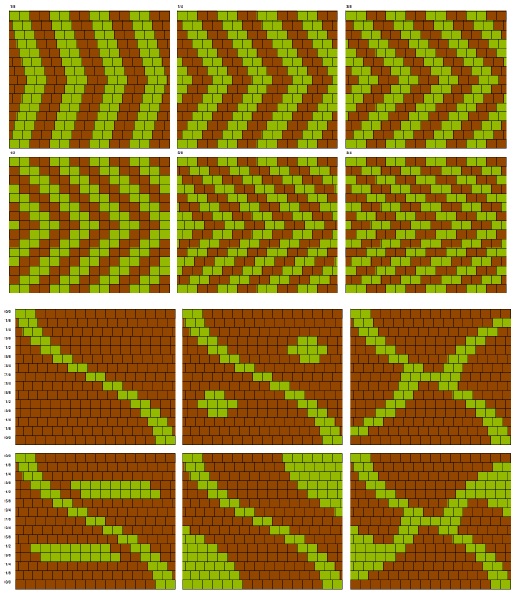

The “Running Bond” Method of installation allows our products to lock anywhere along the 44” (inch) length providing free flowing design capabilities that are unmatched in the industry today. This unique system does not replace our current “step-&-repeat” method of installation…………it compliments it. Each “Running Bond” Method of Installation helps with slight variations during installation, while at the same time allow for custom designs, layouts and patterns as seen here.

If you want your next tile project to look like Pour-In-Place (PIP), this technological advancement further strengthens the idea that architects, engineers, and/or designers can truly provide unlimited design capabilities, layouts and patterns that will compliment any area………………and truly give it that “free-flowing” look (similar to PIP) you have been seeking in a tile/mat/block/paver.

Contact us today to show you our newly patented “Running Bond” Method of installation works; and let us show you how this advancement in design will revolutionize the market of rubber tiles/mats/block/pavers for years to come.

By working with our design team, we can create letters and numbers within our products…..as well as “hopscotch” designs as seen here. Unfortunately, this picture was taken late at night.

w/Measurements:

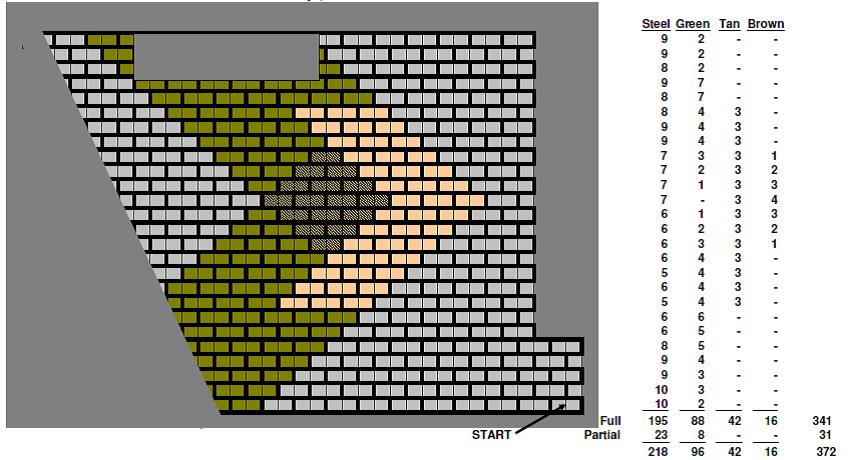

With such advancements in the design capabilities of our products and services, whether you're an owner, operator, specifier, board member or end user, evaluating safety surfacing products such as this can be a daunting task………especially when it comes to budgeting using measurements that are tough to work with.

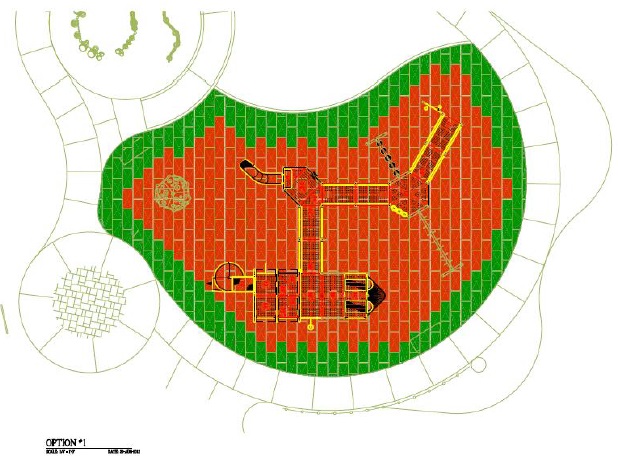

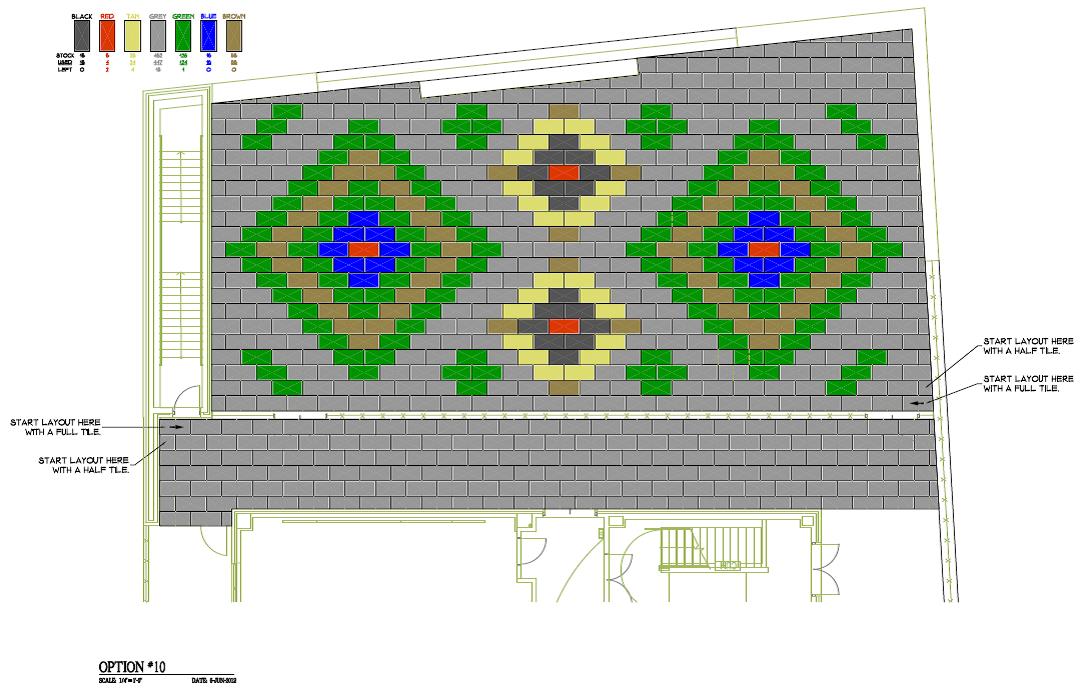

Our staff can offer you and your team unlimited designs, layouts, patterns and color combinations generated specifically to reduce waste, cutting storage and/or stock that are unmatched in the industry today. Have a look at just some of the designs we did for other clients, specifically formulated to reduce costs based on measurements that were provided, either by CAD, PDF or hand-sketch drawing/files.

CAD:

PDF:

If you are looking to incorporate your measurements into an impressive layout, design and/or pattern, you have come to the right place………….it is what we love to do in order to help illuminate waste, cutting, storage, stock as well as our carbon footprint, while at the same time generate a safety surfacing, flooring and paver installation that is truly unmatched.

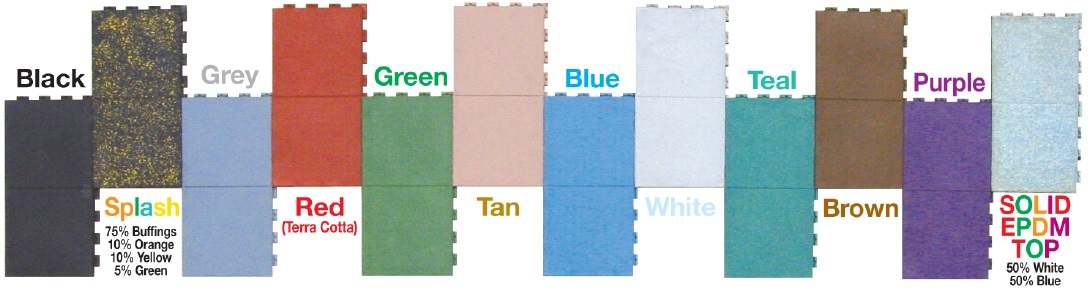

w/Pigmented Colors

All of Unity’s products are made with clean tire buffing and/or crumb rubber granules recycled in-house and mixed with a clear urethane. Colorized products are made with pigmented dyes combined with black recycled rubber that do not release harmful VOC’s, and are produced free of zinc, latex, lead, phthalates and heavy metals. These pigments are dispersed throughout the top of our products for consistency at an economical price. A wide variety of colors to choose from include: black, splash, silver, red, green, tan, blue, white, teal, brown, purple, and TPV/EPDM TOP as noted below.

The colors shown here are for your assistance only. Final selections should be made from the sample chips themselves, which can be obtained by contacting our sales department.

With limitless imagination, our Splash Design (left side) and solid TPV/EPDM top (right side) tiles/mats/blocks/pavers can be manufactured using diverse color combinations and/or percentages generated from a plethora of TPV/EPDM granules listed below.

w/TPV Blending:

Unity has seen more and more architects, engineers and designers looking for unique ways to create additional designs, layouts and patterns in the tile/mat/block/paver system that will provide the “WOW” effect on there next project. With the introduction of EPDM/TPV materials mixed with our current line of recycled products, allow us to generate our “premium series” giving your safety surfacing, flooring and paver application a superior alternative to the pigmented products. Here is a list of the EPDM/TPV color chips to choose from.

The colors shown here are for your assistance only. Final selections should be made from the sample chips themselves, which can be obtained by contacting our sales department.

The colors shown here are for your assistance only. Final selections should be made from the sample chips themselves, which can be obtained by contacting our sales department.

This superior alternative can have unlimited design potential that would compliment any area allowing architects and designers to express design through creativity in blending. Manufactured with Aliphatic Binders, the TPV/EPDM chips exhibit superior UV and color retention and abrasion resistance that will last a lifetime. Free of zinc, lead, sulfur, heavy metals, phthalates and polyaromatic hydrocarbons. It isn’t just taking our products to new lengths, it’s creating unlimited design possibilities with any color combination as noted below:

Chip sizes range from 1-4mm. Chips sizes of 0.5 – 1.5MM is also available upon request.

Click here to view “various design ideas” (w/ Layouts and patterns) we completed for other clients.

Click here to view some of our “Design(s)-to-Concept(s)” (w/Measurements) we did for other clients in the past.

Click here to view some of our past “Designs w/Pigmented Colors”.

Click here to view some of our other “Designs w/ TPV Blends” we did for other clients.