Glue/Adhesive

CX-948 Urethane Glue

Click here to download the Product Data Sheet

Product Info:

|

|

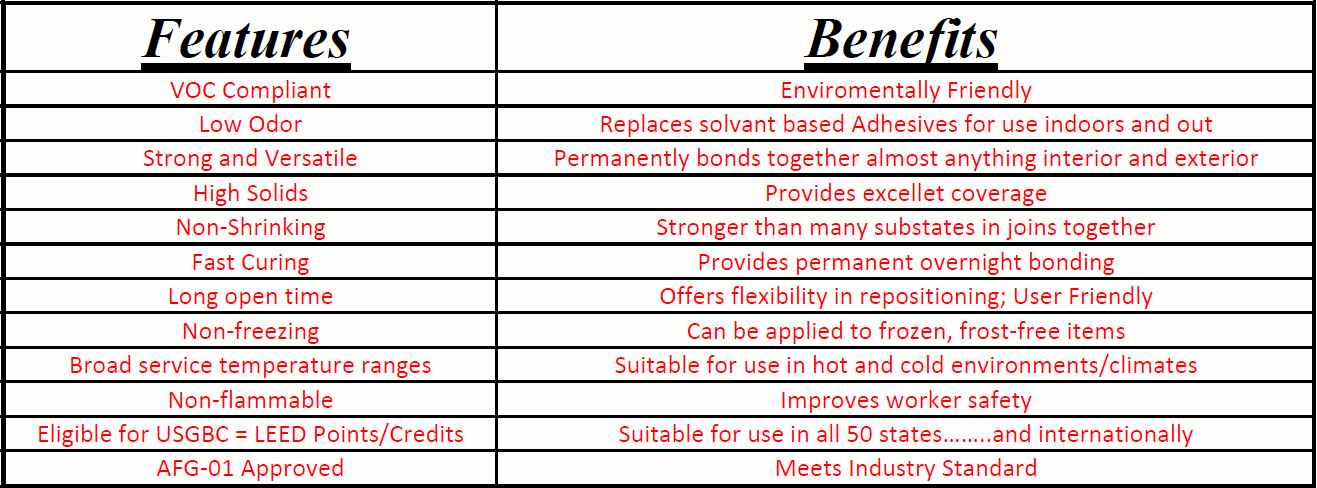

For all of our rubberized safety surfacing, flooring and paver installations globally, there's the CX-948 solution. It is everything you need to install, repair, replace and protect your projects investment for many years to come. The CX-948 is a light brown, one-component, high strength, high-solid, low-VOC polyurethane-based adhesive that is three (3) times stronger than conventional adhesives, with a shelf life of one (1) year. Its patented technologically advanced formula produces a permanent overnight bond to almost any product-to-product, product-to-subbase and product-to-sidewall application.

|

Unity’s glue, as well as its strategic installation application, are keys to our successful installations and reputation in the industry as a single-source provider of all goods used to complete your project. We have grown throughout the years by providing the best and safest glues for our projects through a series of advancements in product design, giving you (the customer) the best bonding in a rubber tile/mat/block/paver.......period. Our urethane glue is used to adhere our product down to the solid sub-straight and to each other (at the interlocking joints).

We advise against gluing this product to roof membranes without consulting with you engineer, architect and local building code requirements first.

Used in any and all types of climates, the high solids provide excellent coverage over the life of your safety surfacing, flooring and paver investment. With the use of our products in conjunction with the glue, there is no shrinking to create loose bonds, or cracking, that is common among other competing products on the market today. The CX-948 is:

- Lap Shear of 240 – 341 based on sub-base applications.

- FHA Bulletin UM-60 approved to meet industry standards.

- AFG-01, FHA Bulletin UM-60, ASTM D 3498 approved to meet industry standards.

- ASTM E-84-95B NFPN, Class A and UBC, Class 1 approved to meet industry standards.

|

|

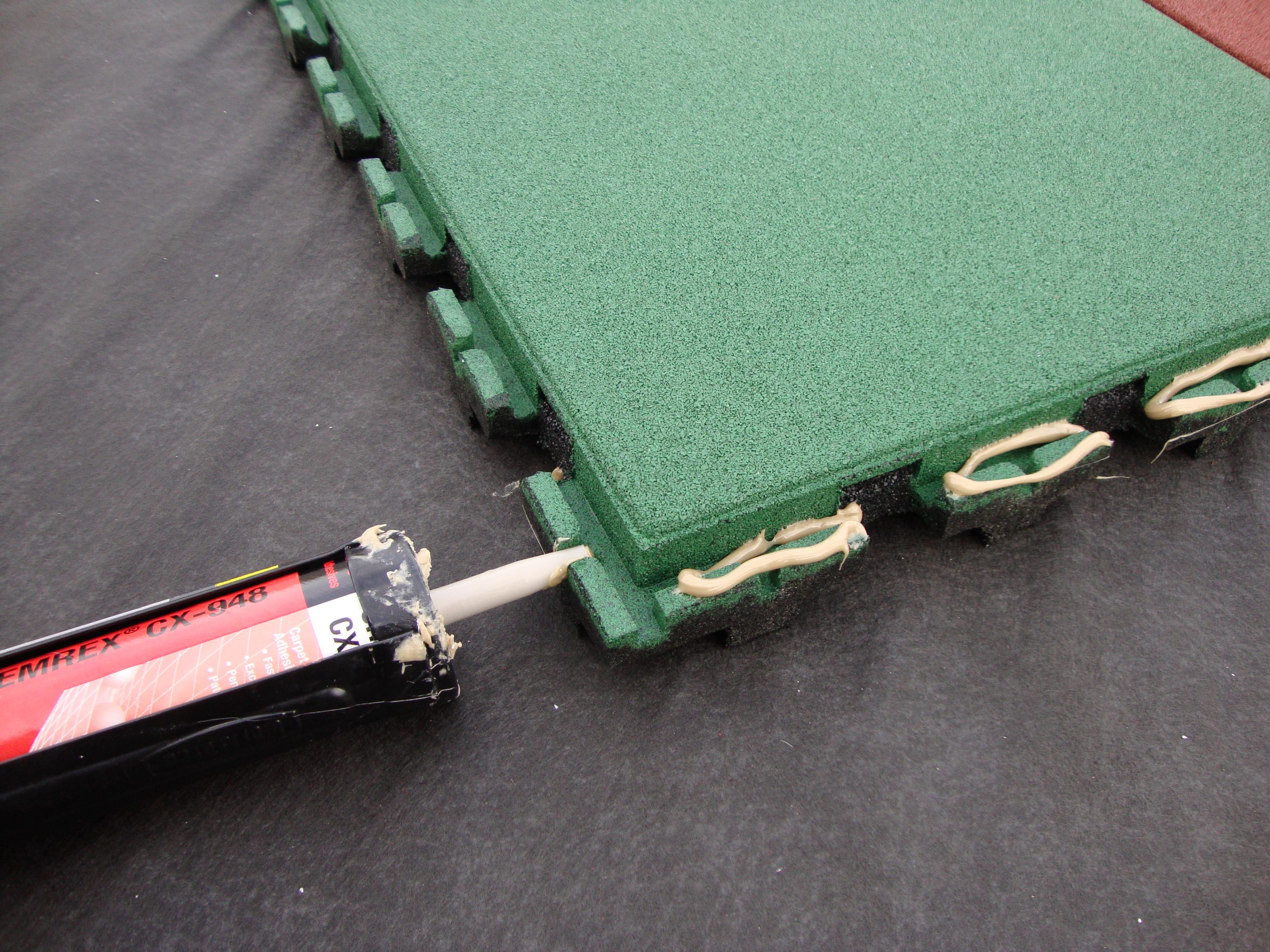

Glue should be applied to both the inside wall and on top (outside edge) of the interlocking joint for a free-flowing adhesion throughout the interlocking system. This will provide FIVE layers of protection that is unmatched in the industry today. It is also used to adhere any and all “lead-in” cut as well. Our self-interlocking joints, along with our urethane glue reduces the need for additional accessory items, such as: pins, clips, fasteners and/or blocks to hold them together, which may never be installed by the installation crew, contractor or end-users......a problem we are seeing more and more.

|

The CX-948 bonds well to most substrates, however, it is the user’s responsibility to check the adhesion of the cured adhesive on specific substrates.The installation area in question, must be structurally sound, dry, clean and free of dirt, moisture, loose particles, oils, grease, wet tar, paint, wax, rust, waterproofing leaks that may affect proper adhesion. During the installation process, it is important to maintain the cleanliness of the area. It is important to store containers in a warm, dry area away from direct sunlight. Storing in elevated temperatures will reduce shelf life, as well as create unnecessary ooze of glue tubes during use. In cool or cold weather; store containers at room temperatures for at least twenty-four (24) hours before using.

Technical Info:

Packaging Options:

858 ml cartridges (12 per case, 48 cases per skid/pallet). | 2- gallon containers (80 containers per skid/pallet) | 5-gallon containers (36 containers per skid/pallet)

Application:

1.) Apply by glue-gun (usually for product-to-product/outside edge of cones underneath) or trowel (usually for product-to-sub base material when installing the transitional ramps as noted above).

2.) Wearing gloves during application is highly recommended. Once material has cured on your hands it is touch to remove.

3.) Do not apply too thin or too thick. Cut the tip (TWICE) using the supplied cutting device on glue-gun to render the appropriate-sized bead.

4.) Use mechanical fasteners or heavy weights to hold materials in place until adhesive has fully cured - usually overnight.

Yield:

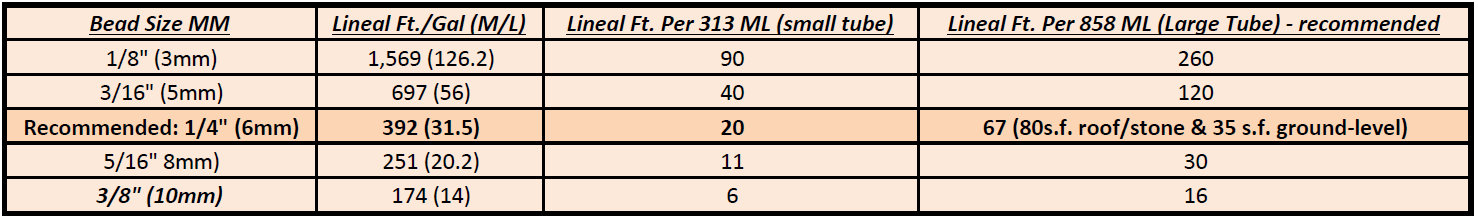

Typically, the tubes will yield ~75 sq. ft. when used on interlocks only; and ~30 sq. ft. when used on the interlocking joints and the underside, outside edge of each tile/mat/block being installed.

Do not glue to roof membranes.

The 2 and 5 gallon containers are typically used for the transitional ramps only. Yields ~100 sq. ft. per gallon, and is not recommended on blacktop/asphalt installations.

Curing:

Our CX-948 forms a tenacious bond overnight. Firm set in 4 to 6 hours; Handle able up to 16 hours, and fully cures in 1-2 days…..depending on weather. This information is based on temperatures at 75 degrees F. (24 degrees C) and 50% relative humidity. Cure times vary with temperature, humidity, and the porosity of the materials joined.

Cleanup:

Clean all tools and equipment immediately after use with xylene, minerals spirits or acetone. Cured material must be mechanically removed.

For Best Performance:

Wear gloves during application of adhesive/glue. Once cured, the adhesive/glue will be tough to remove from your hands. It is not intended for applications with continuous submersion. If adhesion to a substrate is questionable, a test application must be conducted. Make certain the most current version of the product data sheet and SDS are being used; call Customer Service at (1-800) 293-9822 to verify the most current versions. Proper application is the responsibility of the installer/user. Field visits by Unity personnel are for the purpose of making technical recommendations only and not for supervising or providing quality control on the job-site/installation.

Storage:

Store unopened containers in a warm, dry place, away from direct sunlight. Storing at elevated temperatures will reduce the shelf-life. In cool or cold weather, store containers at room temperature for at least 24-hours prior to using.

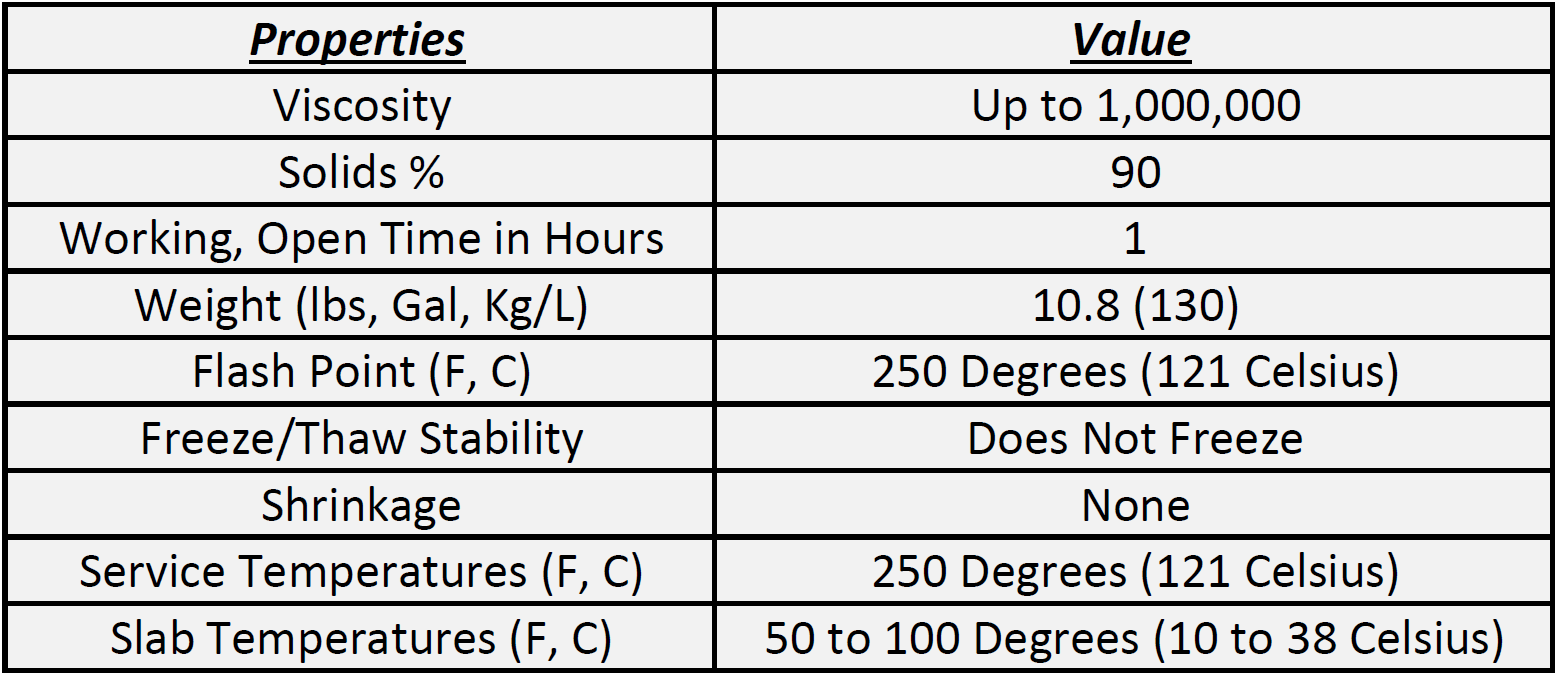

Properties:

Health and Safety:

Precautions:

KEEP OUT OF REACH OF CHILDREN. Avoid contact with exposed skin, eyes and clothing. Wash thoroughly after handling. Avoid breathing vapors. Use only with adequate ventilation. Use impervious gloves, eye protection, and if the TLV is exceeded or used in a poor / ventilated area, use NIOSH/MSHA approved respiratory protection in accordance with applicable Federal, State and Local regulations. DO NOT take internally. Keep containers closed. Empty containers may contain residues - throw away with caution. All label warning must be observed until container is commercially cleaned or reconditioned (recommended to "stay-green").

First Aid:

In case of eye contact, flush thoroughly with water for at least 15 minutes. SEEK IMMEDIATE MEDICAL ATTENTION. In case of skin contact, wash affected area with soap and water. If irritation persists, SEEK MEDICAL ATTENTION. Remove and wash contaminated clothing. If inhalation causes physical discomfort, remove to fresh air. If discomfort persists or any breathing difficulty occurs, or if swallowed, SEEK IMMEDIATE MEDICAL ATTENTION by dialing 911 or call us at: (1-800) 293-9822.

VOC Content:

45 G/L or 0.38 lbs./Gal, less water and exempt solvents.

Click here it see a video on how the glue is applied to the interlocking joints, both inside the channel and along the top of the outside-edge of the same channel labeled: UNITY showing installation of glue at interlocks both inside the joint & on top.

Seller makes no warranty; express or implied, concerning the product furnished here-under other than it shall be of the quality and specifications stated herein. Any implied warranty or fitness for a particular purpose is expressly excluded and to the extent that it is contrary to the foregoing sentence, any implied warranty of merchantability is expressly excluded. Any recommendations made by Seller concerning uses or applications of said product are believed to be reliable and Seller makes no warranty of results to obtain. This data sheet supersedes all previous data sheets for this style and is subject to change without notice.