unblocked games

unblocked games

unblocked games

Soft-Land Product Description

SOFT-LAND Series

|

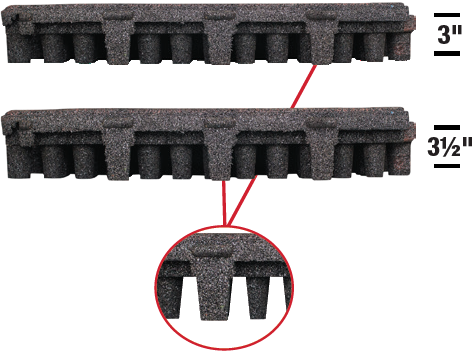

Our 3” and 3.5” thick Soft-Land series is designed to meet and exceed all of your project needs for use on larger scale playground areas, rock-walls, recreational areas, diving boards, etc. where a seven (7') and eight (8’) foot fall rates are needed. It is the foundation for a smart, long-term investment in durability and beauty that will last for years to come.

As the industry leader, the superior raw materials we provide, coupled with our proprietary manufacturing process, unique design and large size product gives you the strongest, highest quality, environmentally friendly rubber tile system above all overs.

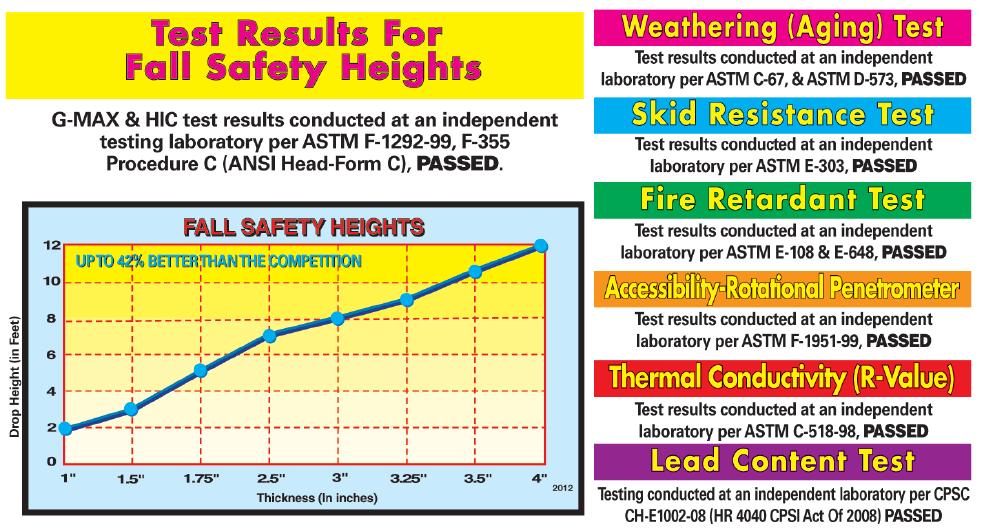

All of our products are independently laboratory tested with respect to ASTM, CPSC, ADA, FM safety standards and guidelines to be installed over new and existing sub-bases and/or rooftops, both indoors and outdoors.

|

|

|

SIZE, WEIGHT, LONGEVITY, SAFETY, QUALITY, DURABILITY is the core of Unity’s products. They are easy to clean and safe to use. They do not displace during usage resulting in consistent shock absorbency year round. The low life costs makes for very good footing while at the same time, prevents leg fatigue.

Soft-Land does not harbor foreign objects, such as glass commonly found in loose filled materials, nor does it require constant maintenance. There are no retaining edges needed and all of Unity’s rubberized safety surfacing, flooring & paver products are accessible to the handicapped. They are also water permeable to allow for “free flow drainage” to a drainage outlet......ideal for storm-water management/flooding issues. They are easy to install and are fully warranted, presenting a superior product that no one can match.

|

.jpg)

|

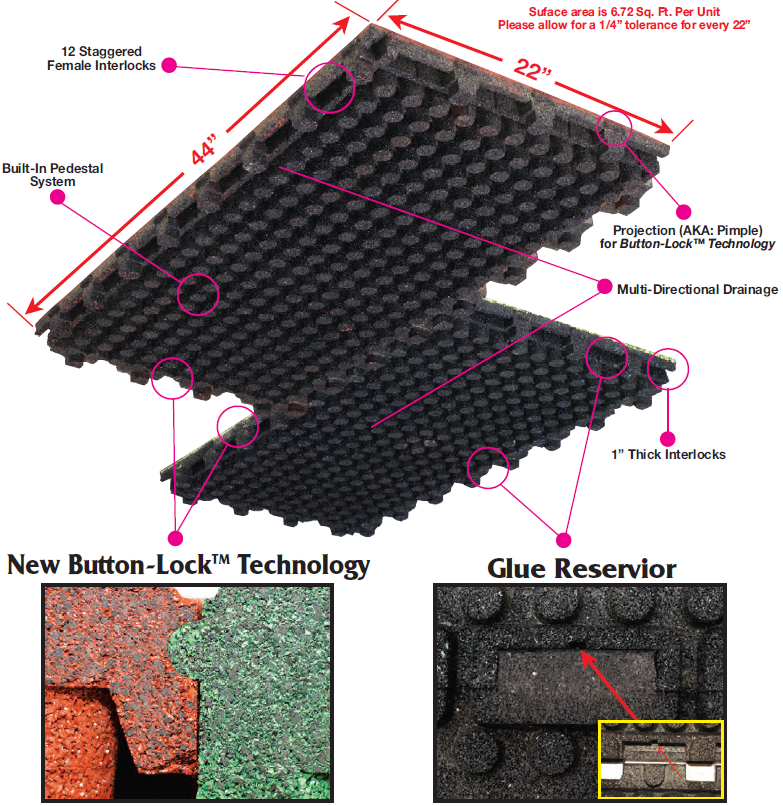

- Built-in Pedestal Designs

- Does not Displace During Usage

- Double Tiles Allows for Faster Installations

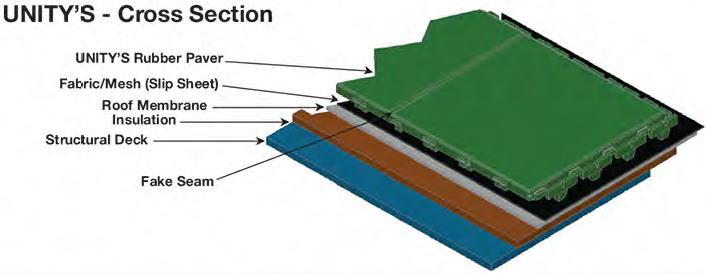

- Provides Thermal and Mechanical Protection

- Can Be Installed on Compacted Stone or Solid Sub-bases

- Conforms to Almost Any Low-Sloped Waterproofing Membranes

- Staggered Interlocks Allow for Free-Flowing Designs, Layouts, Patterns

- Ideal for Tall Playgrounds, Diving Boards, Rock Walls, Indoors / Outdoors

|

Not only is Soft-Land resilient and can be installed over most existing sub-bases, but they are also independently laboratory tested to meet or exceed ADA (Americans with Disabilities Act), ASTM (American Standard for Testing Materials), ANSI (American National Standards Institute)/ FM and CPSC (Consumer Product Safety Commission) safety standards and guidelines.

Soft-Land can withstand heavy blows and high traffic making it a perfect solution for all type of applications (large or small). It is fully warranted, therefore making it a superior product that no one in the industry can match.

Hard materials such as concrete (cement) and blacktop (asphalt) are very unsafe to sit, stand, walk and/or play on, and increases the likelihood of leg fatigue and injury. The bottom line is, they fall short of providing any kind of safety to an area.

Loose filled products such as sand, woodchips, fiber, and/or pea-gravel is HIGHLY dependent on maintenance in order to remain in compliance. Additionally, everyone dislikes the fact that loose filled materials build up in ones sneaker or shoe and can be tracked into a clean home, building, school, facility or daycare center.

Unity solves these problems by providing you with a solid unitary, resilient rubberized safety surfacing, flooring and paver product that is clean and safe to use, indoors and out

Features & Benefits:

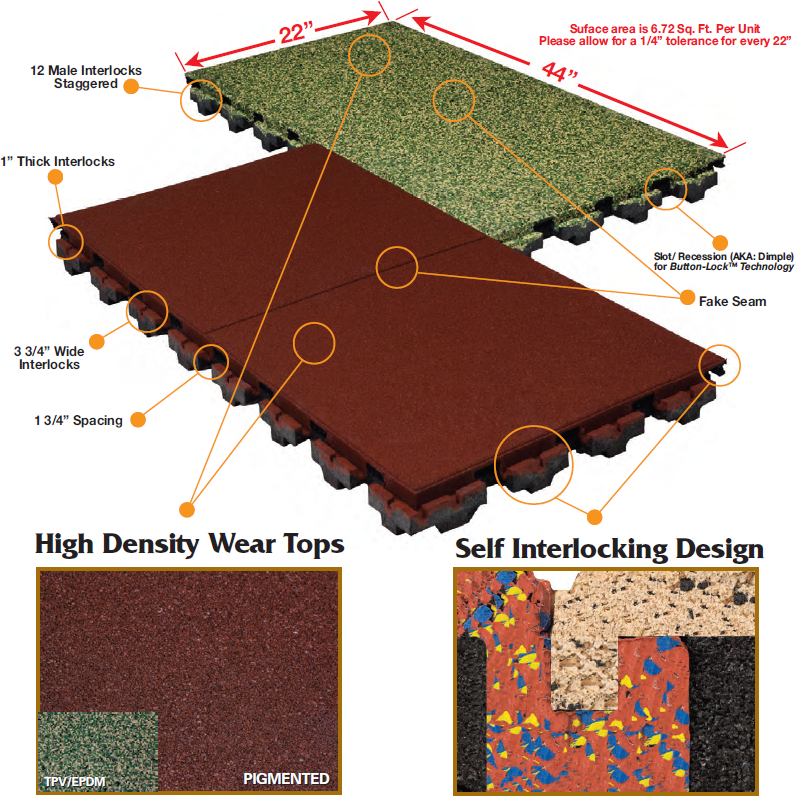

Unlike other playground surfaces, Unity features a flexible double tile/mat/block/paver system. With it has a fake seam down the middle to accommodate and adjust to, minor variations in sub-bases. Our resilient double panel allows us to have a monolithic Step & Repeat pattern, which lines real seams with fake seams as if you were installing “brickwork.” These technological developments in design act as a backup to further resist separation, curling, peeling and vandalism across a playground area. Fake seam force real seams to stay in place.

|

| Our High Density Wear-Top is manufactured using recycled rubber in conjunction with a wide variety of slip resistant Pigments and/or blended EPDM/TPV material, coupled with our specially formulated binders. These high density, textured wear-top options are resilient and won't crack, puncture or heave in the most hostile of weather conditions. This versatility is unmatched and provides year round use to the end-user. |

The patented C-shaped self-interlocking design is built directly into the product itself, It locks tightly together thanks to the supporting "back-wall", which prohibits unnecessary separation, curling, pealing, shifting and wind up-lift. It is installed with our specially formulated glue/adhesive, while still providing unlimited access to sub-base materials for any maintenance related issues. |

|

|

|

A revolutionary advancement in design is out patented "Button-Lock" technology where the projection of one Interlocking tile is receivable by the corresponding slot/ recession of another interlocking tile. It is designed to literally"snap and hook" into place, which provides an extra layer of protection to the end user. This additional locking mechanism provides the most secure installations on the market, both horizontally and vertically. A characteristic that can only be found here.

|

|

This advanced design feature, found on the inside wall of our female interlocks, allows for any access glue to ooze down and away from the top of our products during the installation process. This is thanks to the built-in channeling system seen here.This continual advancement in product design assures architects, engineers, designers, consultants, building owners and operators, end-users and contractors a qualified, professional installation that is fixed and functional throughout the life of the product.

|

|

In this case, size does matter in this case as it allows installers to install (almost) twice the square footage per man hour then the conventional square tiles, a savings that is unmatched in the industry today.

|

|

Our twelve staggered interlocking joints:

1.) Lock tightly together thanks to the new “Button-Lock™” Technology.

2.) Provide faster and easier drainage, allowing no foreign objects to harbor between the interlocks which are commonly found in other competing products on the market today.

3.) Helps prevent our products from shifting away from one another - a necessity in active, “common” areas.

4.) Eliminates future problems such as expansion and contraction which may encourage vandalism.

5.) Allow owners of our products to unlock the tabs in order to remove a damaged product, repair a substrate, or relocate a surfacing/flooring area if necessary.

6.) When loose laid pavers are interlocked over the roofing membrane, it will conform to almost any sloped waterproofing membrane system, old or new, while at the same time providing noise reduction and superior protection without limiting the accessibility to the membrane. This versatility is unmatched and decreases the repair expenses to the consumer allowing, for many years of hassle-free use and enjoyment.

7.) Provide "free-flowing designs" similar to PIP systems.

|

This versatility is unmatched and decreases the repair expenses to the consumer allowing, for many years of hassle-free use and enjoyment.

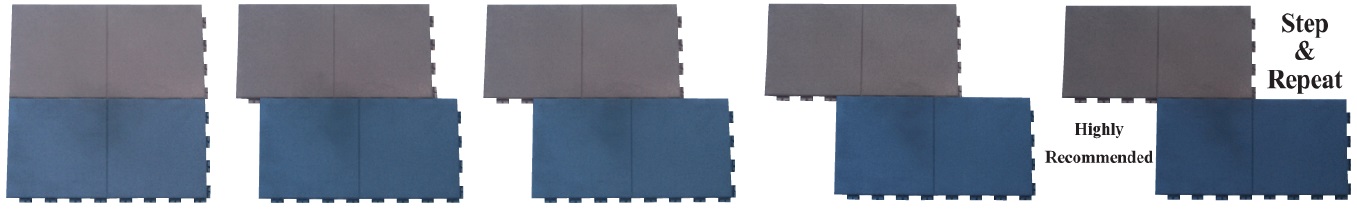

Step & Repeat:

Contributing to design, our interlocking system can provide a monolithic “step & repeat” method of installation that allows anyone to stagger the products interlocking joints anywhere as if you were installing “brickwork”, commonly known as a “staggered bond” or “running bond” method of installation. This technological development acts as a backup to resist product-to-product separation, curling, peeling and most importantly wind up-lift.

These patented systems, along with the sheer size, weight and durability of our product allows architects, engineers, designers, municipalities, building owners and operators to truly set the standard by which all others are measured. Size does matter in this case as it allows installers to install twice the square footage per man hour then the conventional square tiles, a savings that is unmatched in the industry today.

Bolt-Down:

Another patented feature that we have to offer is the BOLT-DOWN capabilities of our products. This unique system is found within the male portion of our interlocking joints to provide added strength and security. It is counter-sunk, and laboratory tested, to avoid any “hard-spots” within the product itself. It is capable of being placed under the most extreme environmental conditions and/or usage. WE DO NOT RECOMMEND THE “BOLT-DOWN” PROCEDURE ON ROOFTOPS WHAT-SO-EVER.

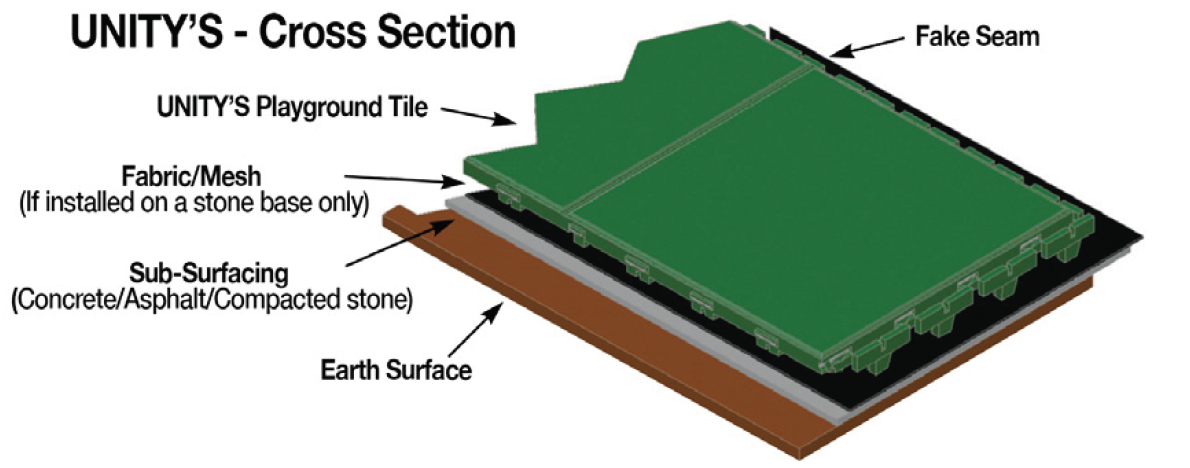

Sub-Base/Installations:

Our products place in the intermediate category regarding installation difficulty. Contractors carry out most of the installations. An installation manual/guide is available upon request (and is shipped with every order). Adhesive must be applied to the solid sub-base and interlocks of our products, both inside the joint and on top. Bolts may be applied to the male interlocks and countersunk for added strength and security. Tools that are common for most installations include: an extension cord for electric use, a utility knife and/or jig saw for cutting, a straight edge to make your cuts accurate, a string line and tape measure. A trowel and/or caulking gun may be needed for gluing purposes as well as a drill for bolt-down applications. As with any construction site, it is always important to have a cleaning compound and medical kit on standby just-in-case.

|

Playgrounds

|

Rooftops

|

|

|

Color:

All of Unity’s products are made with clean tire buffing and/or crumb rubber granules recycled in-house and mixed with a clear urethane. Colorized products are made with pigmented dyes combined with black recycled rubber that do not release harmful VOC’s, and are produced free of zinc, latex, lead, phthalates and heavy metals. These pigments are dispersed throughout the top of our products for consistency at an economical price. A wide variety of colors to choose from include: black, splash, silver, red, green, tan, blue, white, teal, brown, purple, and TPV/EPDM TOP.

EPDM/TPV:

With limitless imagination, our Splash Design and solid TPV/EPDM top tiles/mats/blocks can be manufactured using diverse color combinations and/or percentages generated from a plethora of TPV/EPDM granules listed below.

This superior alternative can have unlimited design potential that would compliment any area allowing architects and designers to express design through creativity in blending. Manufactured with Aliphatic Binders, the TPV/EPDM chips exhibit superior UV and abrasion resistance that will last a lifetime.

|

Thicknesses:

The pre-molded size of the “Soft-Land” products are 22” (inches) by 44” (inches), which equals 6.72 sq. ft. per unit. Please allow for a ¼” tolerance.

|

|

Testing Info:

These critical tests are the value of avoiding legal problems resulting from lawsuits that stem from inappropriate ground cover.

|

|

|

|

Unity meets or exceeds these ASTM, CPSC & ADA Standards by up to 40% when compared with other competing products on the market today.

Click here to download our Soft-Land series “Product Data Sheet” for your review and consideration on you next project.